Lanes no dig technology on shopping list for store construction firm

A construction company had Lanes for Drains ‘no dig’ technology and expertise on the shopping list when it needed to urgently solve a drainage problem just before the opening of a new supermarket.

Lincolnshire-based civil engineering firm Britcon called in Lanes for Drains, the UK’s largest independent drainage specialist, to carry out a pre-handover survey and final clean of drainage lines at the food store in South Yorkshire.

HD video footage from a remote-controlled robotic camera, operated by the Lanes engineers, showed a wooden stake had penetrated a storm drain underneath the building.

The conventional solution would have been to dig a hole in the floor of the new supermarket to reach the pipe and remove the stake – which would have delayed the opening of the store and incurred significant costs.

However, engineers based at the Lanes for Drains depot in Sheffield, South Yorkshire, were able to advise that their no dig expertise meant the solution would be far less drastic and time-consuming.

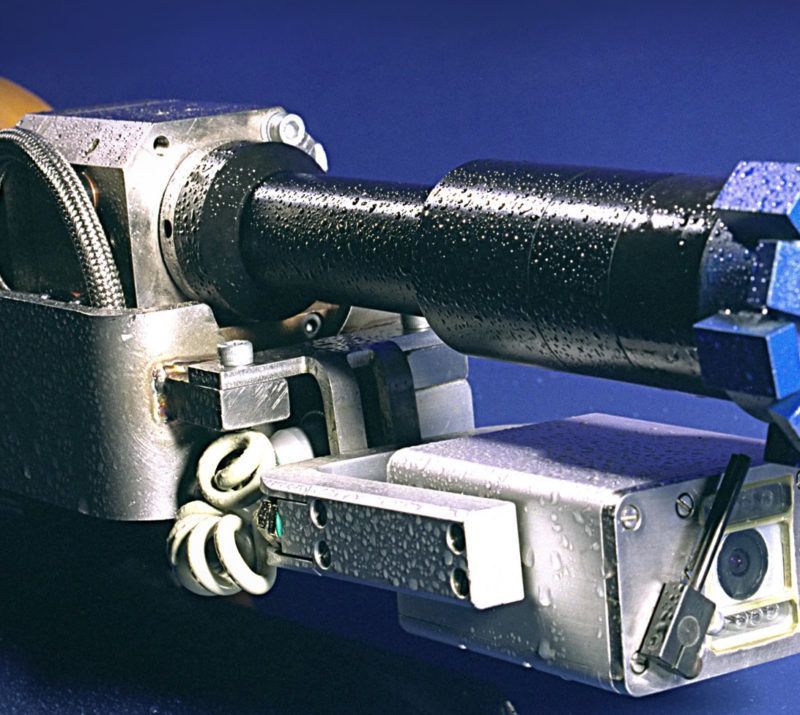

They were able to deploy a powerful remote-controlled KA TE robot cutter, recognised as being best machine of its kind in the world, sending it through the pipe, underneath the building, directly to the location of the wooden stake.

The Lanes engineer used a camera on the cutting tool, used to clear a wide range of blockages in drainage lines, to guide it into position and grind off the stake.

James Oates, Lanes for Drains Area Development Manager for South Yorkshire, said: “The client was relieved that we had this ‘no dig’ technology available.

“It was important that the stake was removed. If it had been left in place, it would have, almost certainly, eventually caused a blockage.

“This is precisely when pre-handover drainage surveys are for. In most case, they confirm what the civil engineers already know and allow the lines to be cleared of any building debris using our jet vac.

“But if a problem is found, it’s important that you have the right equipment, experience and skills to deal with it quickly and cost-effectively. In this case the problem was rectified in less than half a day and the store opened successfully on time.”

Lanes for Drains has three of the Swiss-made KA TE DN 150/300 robot cutters, more than any other drainage specialist in the UK, representing a capital investment of nearly £1m in the advanced technology.

Each cutter has its own support van, carrying the powerful hydraulic compressors that power the machines, and is operated by teams of two or three engineers depending on the scale of the cutting job.

The cutting is done by a grinding wheel made from PKD industrial diamonds, diamond granules or tungsten, depending on the material being cut, that can be positioned precisely by the operator anywhere within the pipe.

Lanes for Drains uses the KA TE cutter to clear tree roots, cut through metal spikes, clear scale build up, grind down concrete, clay and plastic pipes in intruding connections and reopening connections in relined pipes.

Jon Close, a project manager for the Lanes Group’s Sewer Renovation Division, who has overseen the company’s deployment of the technology, said: “The KA-TE cutter is no doubt the best robotic cutter of its kind in the world.

“It’s an essential piece of kit for our sewer rehabilitation teams. Its awesome capability, speed and power means it allows is to keep up with demand for our services.”