High Level Cleaning

Client: London Underground Sector: Underground Location: London

Project challenge

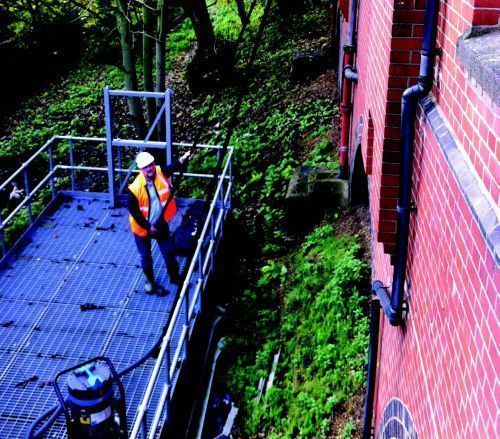

Lanes Group Rail Division carries out gutter cleaning on buildings, including stations, for London Underground. Many high level areas on these buildings are difficult to access. Also, many of the buildings are ageing, with relatively fragile roof structures. Station buildings can only be worked on at night.

Faced with these challenges, Lanes is always looking for innovations that will improve productivity, health and safety, quality and staff working conditions. This led to the trial and introduction of the SkyVac guttering cleaning system.

The project

Lanes Rail Division has five permanent gutter cleaning teams operating across London Underground’s estate.

Keeping gutters clean is important to support the long-term structural integrity of buildings, a number of which are listed. Many of the buildings are ageing, and were not designed to support maintenance programmes that meet modern standards of health and safety, or encompass modern cleaning techniques.

This results in the need for Lanes to use a range of methods for working at height, and associated access equipment, including scaffold towers, full scaffold systems, and powered access equipment. In some cases, up to half the time on a shift is taken up with setting up and breaking down access equipment.

The equipment also has to be transported to and from work sites, reducing the sustainability of working practices. These issues led Lanes Rail Division to carry out a trial of a UK-designed wet and dry vacuum cleaning system called SkyVac.

It allows operatives to stay on the ground while cleaning gutters to a height of up to 12 metres. It has poles made from carbon fibre, making them both light and strong. A mini camera can be attached to the cleaning nozzle to help the operative control the equipment and monitor cleaning quality. The camera also takes still images that can form part of a client performance report.

Within six months of SkyVac’s introduction, two of the five gutter cleaning teams were using it, with plans to increase its use, especially to work on station canopies where there are limitations on site access.

Client benefits

- Improved health and safety through reduction in working at height.

- Improved productivity, by reducing setup and breakdown times.

- Reduced cost, through a reduction in need for access equipment.

- Greater staff satisfaction, through ease of operation and system effectiveness.