No-Dig Technology

If you are looking to arrange drain or sewer repairs for rail facilities without disrupting services, our no-dig technology is the perfect solution. At Lanes Rail, we have years of experience using no-dig technology to deliver vital repairs with minimal fuss.

This advanced method of drain repair without digging uses sophisticated CCTV imaging and resin relining to fix cracks and defects within a drain or sewer from the inside, using compact automated equipment that does not require any excavation. This trenchless technology delivers long-lasting results that will have your pipes and sewers back in perfect working order in no time.

Lanes Rail is a specialist provider of drain repair services without digging for the rail sector. We can be contacted 24/7, and will be able to deliver a cost-effective and highly responsive service that meets all of your needs.

To learn more about arranging a dig-free drain repair for the rail sector, give us a call on 0800 526 488, or use our online enquiry form to request a call back.

What is no-dig technology?

No-dig technology has become Lanes’ go-to pipe repair method for the vast majority of cases we attend, and involves the installation of a cured-in-place pipe (CIPP) repair or liner inside your existing pipes to fix leaks or structural damage.

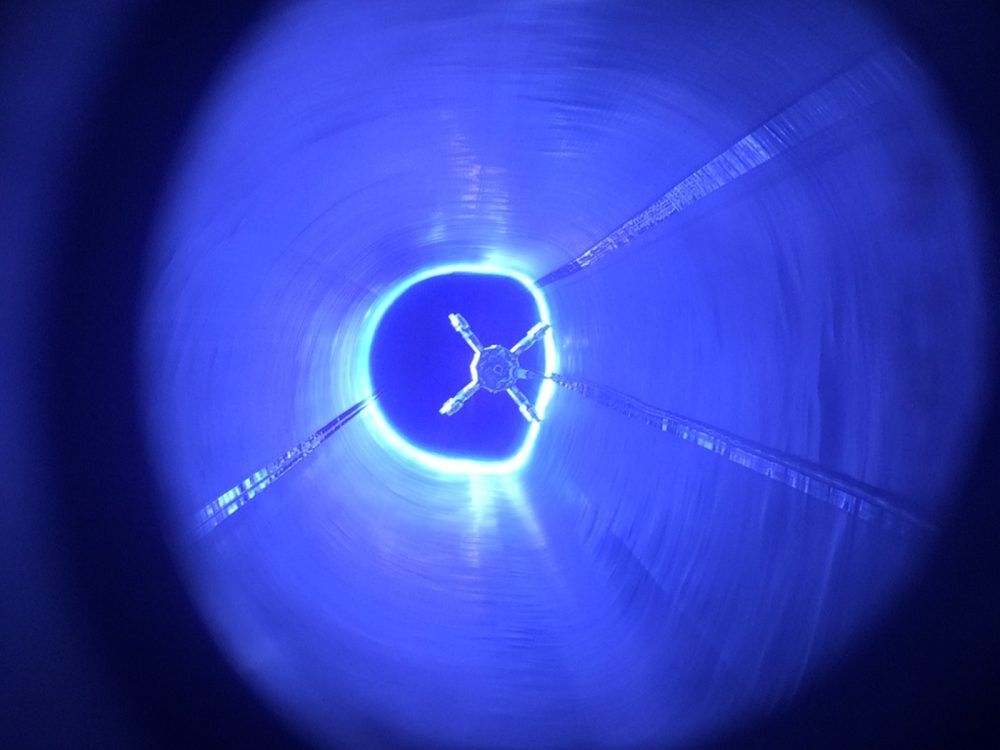

First, we use jet vacuumation to empty out the pipes, before sending a robotic CCTV unit to identify defects and make a note of the location of connections and junctions in the drain system. This allows us to then insert a liner containing a special resin along the length of the pipe

Once the liner is in place, it is turned inside out and pushed out to bond with the interior of the pipe using either water or air pressure. Ultraviolet light is used to cure and harden the resin in place, essentially creating a new pipe within the old one and getting the drain back in normal working order.

We are able to use this method for drain repair without digging for pipes of all sizes, ranging from small passages of 100mm in diameter, all the way up to 1.8-meter sewers and culverts. In cases where a localised repair on a short section of the drain is needed, we may employ CIPP patch (or point repair) lining, which involves fitting a small patch of CIPP liner for a specific section of pipe.

What are the benefits of no-dig technology?

No-dig technology has been developed as a means of efficiently and effectively repairing drains and sewers, without first needing to excavate large sections of the pipework. This method provides a number of crucial benefits for your rail facility:

- Drain repairs without digging can be successfully completed without the disruption caused by excavating land, roads or pavements – all that is required is that our engineers are able to access the pipe from manhole chamber to manhole chamber

- Suitable for all types of horizontal or vertical sewers or drains, including refuse chutes and downpipes

- Long-lasting results, with design lives of at least 50 years on our liners, or up to 120 years when using our innovative fiberglass UV liner

- Ideal for both emergency drain repairs and proactive maintenance work, allowing you to detect and fix drain defects before they become a serious problem

- Competitive pricing, calculated according to the specific needs and requirements of your job

No matter what kind of repair and maintenance work is required for your facility’s drains, pipes, and sewers, no-dig technology is likely to be the least disruptive and most cost-effective solution in almost all circumstances. You can learn more about this service by checking out our drain relining guide.

Why choose Lanes?

By choosing Lanes Rail for your no-dig sewer renovation and rehabilitation work, you can place your trust in one of the technology’s leading pioneers. We were among the earliest adopters of no-dig technology in the UK, and we continue to be respected as one of the most capable providers of trenchless repair services in the country.

Lanes is always working with international manufacturers and industry bodies to deliver the most innovative materials and techniques for our customers. We test our lining materials for at least 1,000 hours to ensure they meet industry standards, but thanks to our outstanding safety practices, we can offer a safety factor of x2, meaning the life expectancy of our liners is usually double the guaranteed minimum.

All of our installations are tested and verified by Pipeline Developments Limited to ensure further confidence in the quality of our work, and our nationwide team of engineers is among the most experienced in the business in delivering this kind of work.

Lanes currently holds the UK record for installing the longest single length of liner in a sewer, which underlines our ability to manage projects of any scale. We take a bespoke approach to planning each job, meaning we can deliver effective results and minimise disruption for even the most congested rail stations.

With depots across the country, Lanes Rail is ready to deliver industry-leading drain repair services without digging to sites across the UK and can be contacted 24/7.

Find out more

If you would like to find out more about our innovative no-dig technology, or discuss the best way of delivering essential drain repair services for your rail facilities, get in touch with Lanes Rail today.

Simply give us a call on 0800 526 488, or use our online enquiry form to request a call back.