UV Lining

Here at Lanes, we take advantage of the latest advances in drain repair and no-dig technology to deliver the most effective solutions with the least disruption for clients. Our state-of-the-art ultraviolet (UV) lining process is a key part of this, and we continue to invest in new cutting-edge equipment to help us make crucial repairs to collapsed or damaged pipes in a way that’s quicker and more cost-effective than ever before.

Here at Lanes, we take advantage of the latest advances in drain repair and no-dig technology to deliver the most effective solutions with the least disruption for clients. Our state-of-the-art ultraviolet (UV) lining process is a key part of this, and we continue to invest in new cutting-edge equipment to help us make crucial repairs to collapsed or damaged pipes in a way that’s quicker and more cost-effective than ever before.

With UV lining, our engineers are able to fix damaged drains and sewers without having to dig up and replace large sections of deeply-buried pipes. And this method offers some advantages over conventional cured-in-place pipe (CIPP) repair techniques in many instances.

Read on to find out more about how UV lining works, and the benefits it can deliver; alternatively, you can call us on 0800 526 488 for more information, or fill out our online enquiry form to request a call back to suit you.

How does UV lining work?

The basis of UV drain lining is similar to other forms of CIPP relining: a liner layered with special resin is inserted into a sewer or drain, before being turned inside out and forced through the pipe by either water or air pressure. The resin then bonds to the surface, creating a new pipe within the old damaged pipe.

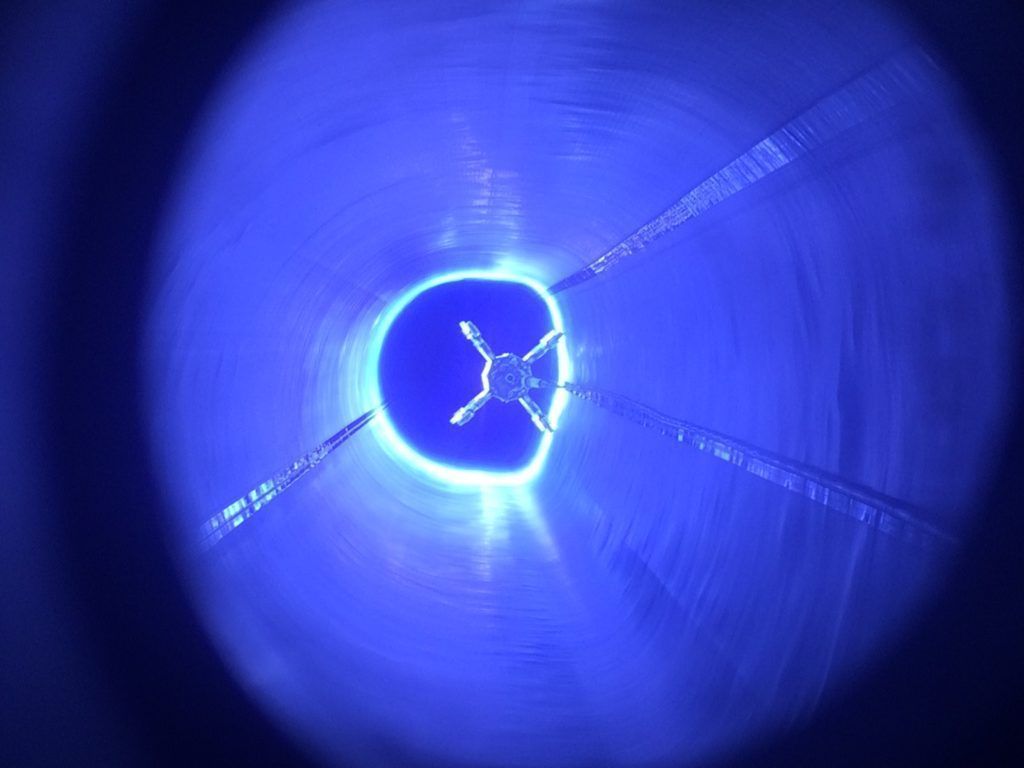

The next stage is to cure the resin in the liner. Older methods like hot-cure CIPP involve pumping heated water through the liner at a given temperature for a specified time to cure the material. This can be time consuming and energy heavy. UV lining is quicker and greener, as the resin in the liner cures under UV-light from a light train which travels through the pipe. This method cures a liner at a super-fast one-metre-a-minute.

As such, UV lining has become the go-to solution for most drainage repair jobs; you can find out more about how this process works with our in-depth guide to drain relining.

What are the benefits of UV lining?

UV lining CIPP offers similar basic benefits to other CIPP methods in that it provides long-lasting repairs to sewers and pipes without the need to excavate, and can be completed in hours or days rather than weeks.

However, the UV method also offers some additional advantages. Compared to more traditional no-dig CIPP, it is faster, with an impressive cure rate of just one metre per minute. UV also requires less equipment, so site set-up and take-down is quicker, making it especially suitable for busy locations like roads, railways and airports, or for geographically awkward sites where there is limited room to manoeuvre.

What’s more, UV provides environmental benefits over the hot-cure method which generates styrene-contaminated water that must be disposed of as hazardous waste. UV lining does not produce any by-products so is safer and more cost-effective.

It should be noted that hot-cure CIPP still has its place and is widely used, for example, where there are bends in the pipe, the pipe is longer than 300-metres or is badly deformed so that the liner may snag and rip as it is being pulled through. It’s important therefore to take advice from an expert drainage solutions provider, like Lanes, who will prescribe exactly the right method for your project.

Why choose Lanes?

As the UK’s largest privately-owned specialist drainage contractor, Lanes Group is ideally placed to fulfil all of your UV lining and drain repair needs.

Recognised as a pioneer in the use of UV lining in the UK, Lanes has won many UKSTT awards, including one for installing the country’s first chemical-resistant UV liner at the Solutia factory in Newport, South Wales, in 2016. More recently we have spearheaded the installation of UV liners in motorway drainage pipes as part of Highway England’s smart motorway programme.

Our investment of over £1-million in three dual-core UV lining systems from ProKASRO has resulted in us offering faster curing, reduced energy usage and greater control. These systems have been designed to our own specifications and come equipped with a sophisticated digital monitoring system so that we continuously improve performance and supply to clients. Read more about this technology here.

Along with delivering relining efficiency and innovation, we have vast experience in managing large-scale projects without impacting on our clients’ day-to-day business operations. For more substantial schemes, our individual project managers provide further assurance and expertise.

Contact us

If you have any queries about our UV lining services, our experts are on hand to answer your questions. Call us today on 0800 526 488 for a free quotation, or fill out the online enquiry form.